Description

This workshop is ideal for anyone who wishes to gain a solid understanding of reliability improvement and condition-based maintenance. You will understand why you should improve reliability, what is involved in implementing a program, and what all the roadblocks will be. You will have a clear understanding of the strategies, philosophies, and terminology associated with the very important process of improving reliability and performance. The course is perfect for managers, engineers, maintenance & operations managers, and condition monitoring leaders.

The three day workshop will cover the following:

- A big picture overview

- The benefits of reliability improvement

- How to assess the benefits for your organization

- How to develop a reliability culture

- Selling the program to senior management

- Developing the program strategy

- Understanding failure and failure modes

- Defect elimination

- Developing an asset reliability strategy

- Work management (planning and scheduling)

- Spares and material management

- Precision and proactive maintenance

- Condition monitoring

- How to break out of the reactive maintenance cycle of doom

- Continuous improvement

- A summary of the implementation strategy

If you complete the three day workshop you will be eligible to take the two-hour, 60-question, multiple-choice ARP-CAT I exam on 13 November 2019. The cost of the exam: $275 per student.

PLEASE NOTE:

ARP I has a dual focus: Asset Reliability Transformation (how to start and run a successful program), and Asset Reliability Execution (the technical steps that improve reliability). You need to view both parts in order to be eligible for the ARP certification.

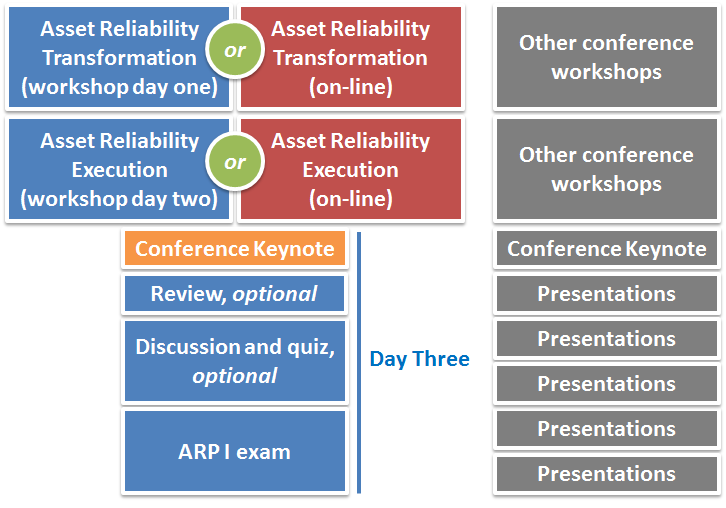

So that you can attend other workshops and technical presentations during the conference, you can decide which parts of ARP you attend live versus online.

You can attend ARP Day One “Asset Reliability Transformation” as part of your ARP I certification, or just because you want to learn about those key implementation topics (i.e. you don’t have to take the ARP exam, the workshop is ideal for anyone interested in the topics listed below). And again, you can attend ARP Day Two “Asset Reliability Execution” as part of your ARP I certification, or just because you want to learn about those key technical topics.

Asset Reliability Transformation: On Day One of the conference, we will focus on how to successfully implement a reliability improvement initiative. This is critically important given the low success rate of reliability programs. We will cover the benefits of reliability, how to assess the financial value of your program, how to assess the risks faced by the organization, how to initiate the program, how to develop a culture of reliability and performance improvement, how to establish KPIs, and how to break out of the “reactive maintenance cycle of doom”. If you follow these steps you will set your self up for reliability success.

Asset Reliability Execution: On Day Two of the conference, we will focus on the technical execution side of reliability improvement: assessing risk (criticality ranking), identifying bad actors (Pareto analysis), developing the asset strategy(RCM, FMEA, PMO), root cause analysis, reliability data analysis, work and spares management, condition monitoring,and precision and proactive maintenance (balance, alignment, lubrication).

On the third day of the conference, we will help prepare you for the ARP exam, and we will deliver the ARP exam. The day will begin with the conference keynote address and then provide an overview of the asset reliability transformation and technical execution process. There will be ample time for discussion, questions, and answers. We will then conduct a detailed interactive quiz which always generates lots of valuable debate and discussion. And then, in the afternoon, you can take the exam.

In order to be certified ARP I, you must either take the “Asset Reliability Transformation” videos on-line or during the Day One workshop, you can either take the “Asset Reliability Execution” lessons online or on Day Two of the conference, and you must take the exam. The review sessions, discussion, and quiz are very beneficial, but not required. You may choose to attend conference technical presentations instead.

Bio

Terry is the Director and Senior Instructor for the Reliability Institute of Australia, an authorised Mobius Training Partner. Starting his career as a Mechanical Engineer, Terry has over 35 years’ experience in the delivery of products and services that support improvements in equipment maintenance and reliability.

Terry is the Director and Senior Instructor for the Reliability Institute of Australia, an authorised Mobius Training Partner. Starting his career as a Mechanical Engineer, Terry has over 35 years’ experience in the delivery of products and services that support improvements in equipment maintenance and reliability.

He spent 4 years as General Manager of Mobius Institute, the world’s leading provider of accredited reliability & vibration training and certification, supporting and appointing Mobius’s Training Partners throughout the world.

Prior to that, he spent 8 years running an Industrial Maintenance Roundtable, facilitating a collaboration and information sharing network with over 45 major industrial companies. Before that he worked for SKF Australia for over 20 years, in various technical and management roles. His last position was General Manager for SKF Reliability Systems, responsible for providing condition monitoring services, installation services, reliability improvement projects, sales of predictive maintenance equipment and delivery of training courses.

Terry is an effective communicator and has delivered reliability training courses in Australia, Malaysia, New Zealand and South Africa.